10 Years of Central European Staffing – NRL welding tests (2013-2014)

NRL is a UK based provider of recruitment, training, rail maintenance and non-destructive testing services to the technical, engineering and construction industries. In 2013 and 2014 Central European Staffing provided coded welders for NRL’s two engineering projects in the UK – in the shipyards near Edinburgh and Middlesbrough.

Central European Staffing recruited all the candidates in Poland. NRL representatives monitored the testing. They also monitored the welding inspectors during each stage of the trade tests and certification process. They then faced and passed rigorous skill-verification, including task-training and practical testing.

A welder during his training day welding a root pass.

In the first stage, we screened each candidate for welding experience and qualifications.

The second stage was a two-day visit to our Warsaw-based welding facility. The first day focuses on pre-selection and training. The welders familiarise themselves with the machines and special welding consumables shipped from the Netherlands. Candidates review WPS documents, procedures and safety requirements.

Note: the welding facility we use has an ISO-17025 accredited laboratory, where all necessary tests are performed quickly and professionally. Only welders whose performance is acceptable move onto the second day of practical testing.

On the second day the welders work with essential materials: carbon steel pipes with the two test pieces varying in thickness as well as consumables. Each welder has to complete the task according to WPS standards following all listed procedures. This includes preheating, temperature verification, changes in polarity and welding rods, gas flow and the like.

Anyone failing to successfully complete any of the procedures is immediately dismissed.

A welder performing a test on an assigned test piece

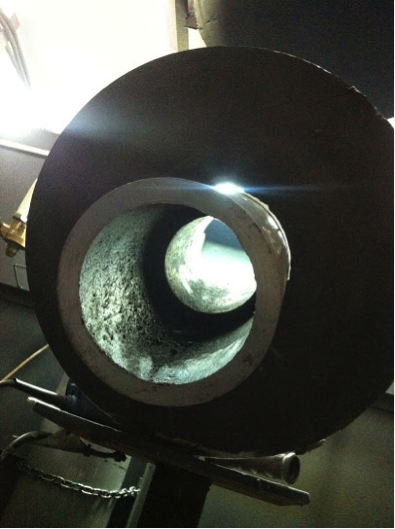

The welding was performed according to MCAW/FCAW (138/136) methods in 6GR position (H-L045 with restriction ring fitted 1 cm above the edge).

A test piece in 6GR – a cooling-off break is necessary to reach the required interpass temperature

A pipe in 6GR position – visible varying thicknesses of the pieces

Central European Staffing organised welding tests in batches of 20-30 candidates starting July 2013, with the last round being completed in May 2014.

We conduct all test procedures in accordance with EN287-1 (EN9606-1 since February 2014), ASME and AWS requirements. Candidates obtain certificates in all three standards per project specifications. Each test piece was radiographed and underwent a mechanical bend and penetrant test.

Test pieces on display

Central European Staffing tested circa 250 MCAW/FCAW welders throughout 2013 and 2014 with a pass rate during the last test rounds of approximately 80%.

Of those successful candidates, 110 went to work in the UK.